Â

A computer numerically controlled (CNC) machinist is a job you may have never heard of before. This job is essential to the manufacturing of many common, household goods and machinery. For more information on what CNC machinists do, a manufacturing quote, as well as employment opportunities, visit United Scientific INC online now.

What Does a CNC do?

Now that you know what CNC stands for, you’re probably wondering what does one of these machinists do, exactly?

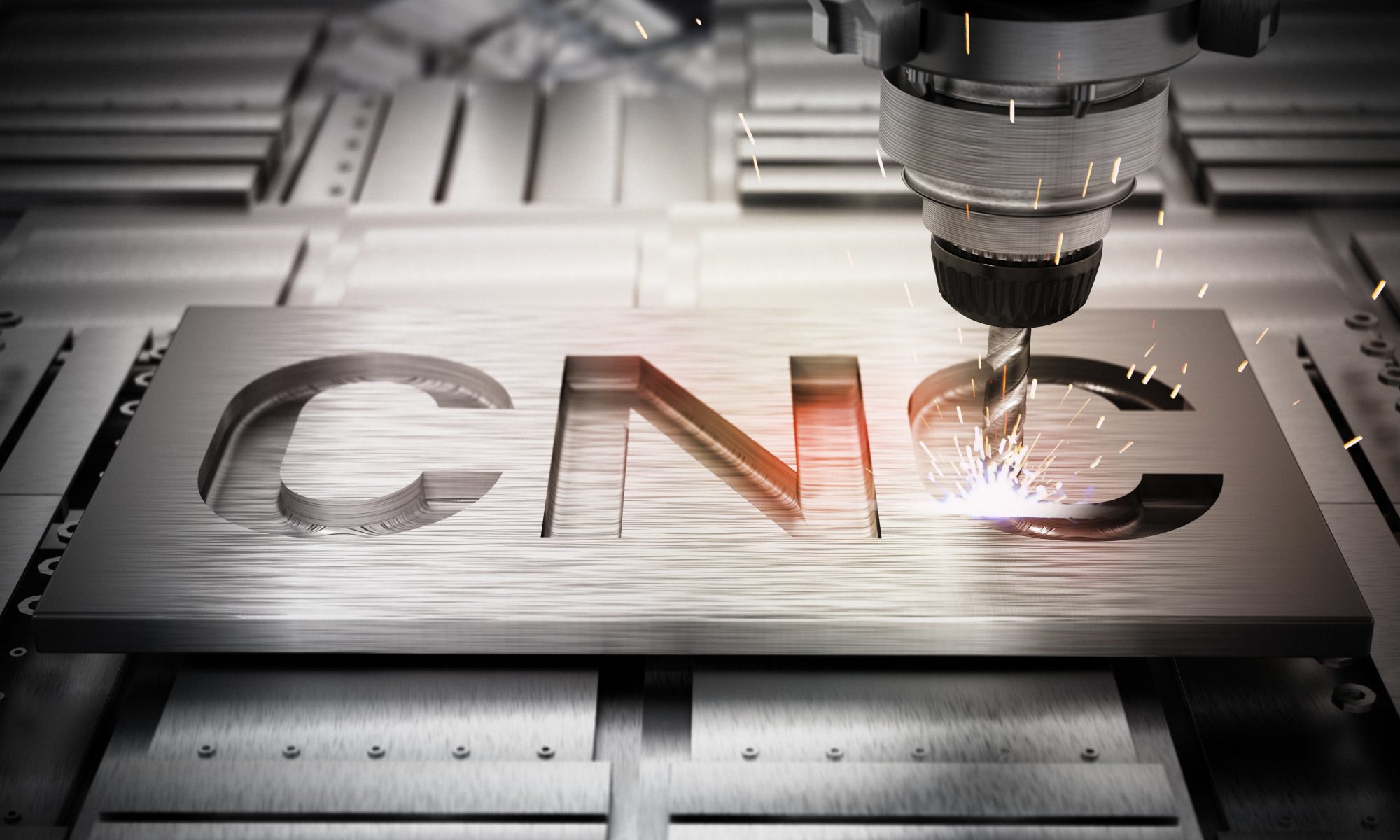

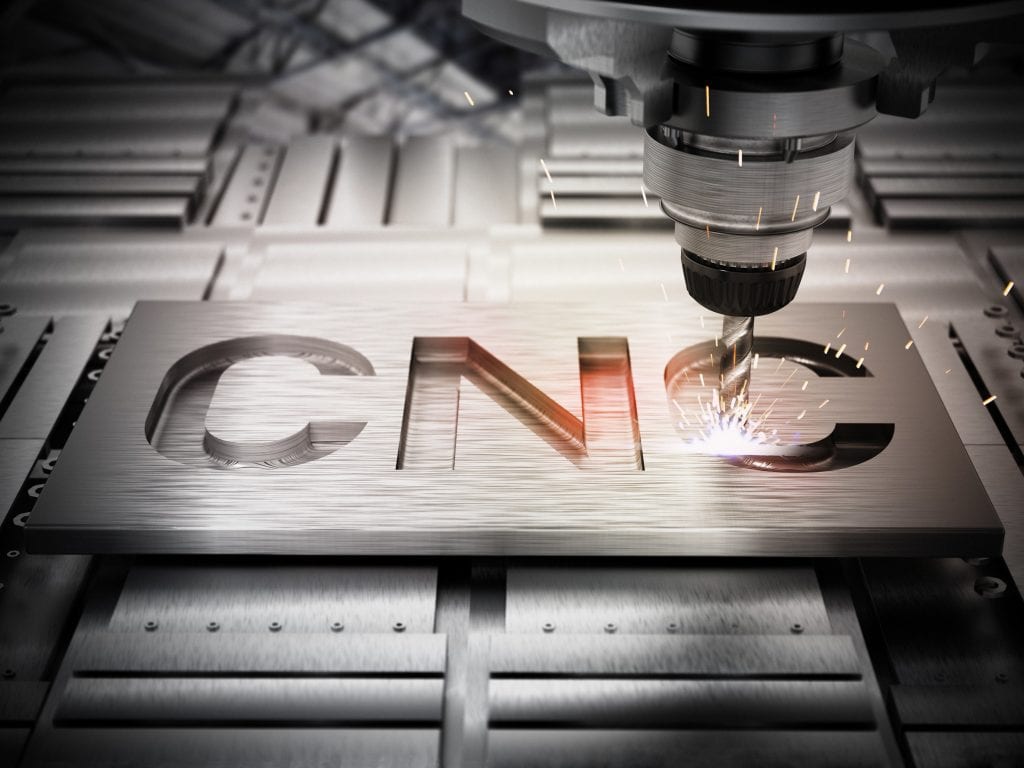

Simply put, CNC machinists help create parts for larger products by mapping out the specifications of these parts on computer software. The instructions the operator inputs then give an instrument operating instructions, and the ability to make these machine parts.

These commands that are created by an engineer control the speed, movements, and other factors to create the perfect product, whatever it may be. CNC machining is the result of technology and man-power working in total harmony

For example, a computer numerically controlled machinist doesn’t manufacture a new car. They are responsible for a smaller piece of a car–something like a fuel injector or upper shock mount. CNC companies and machinists produce some of the smaller, yet critical parts, that make up all cars.

These machinists use a variety of equipment to create each product or prototype. Some of the different machines they utilize are::

- Milling

- Turning

- Waterjet cutting

- Laser cutting

- Turret punching

- Plasma cutting

Additionally, there are a plethora of materials used in CNC machining. Some materials you may see on the job are:Â

- Brass

- Titanium

- Aluminum

- Copper

- Stainless steel

- Steel

- PVC

- Polycarbonate

The number of unique products that machinists manufacture, and the equipment they use to make those products can almost guarantee that no two CNC positions are the same.

What Industries Use CNC Companies?

One of the most exciting things about computer numerically controlled manufacturing is the variety of industries that utilize their services. With each new client, new products need to be developed and manufactured, making each product and day a little different.

Here are some of the industries that utilize the services provided by a CNC:

- Construction

- Automotive

- Defense

- Medical Devices

- Food Processing

- Transportation

- Recreational Equipment

- Agriculture

- Aerospace Technology

- Oil and Gas

Amazing, isn’t it? CNC machining is a crucial component to almost all modern product manufacturing.

What Makes a Good CNC Machinist?

It turns out that certain qualities correlate with being a fabulous computer numerically controlled machinist.Â

If you find yourself being excellent at:

- math

- have great control of manual dexterity,

- maintain extraordinary attention to detail

- have remarkable problem-solving skills,Â

- have a significant understanding of computers

- preserve superb physical stamina

Being a CNC machinist may be the dream job you never knew you wanted.

CNC machining is a career that is the perfect combination of creativity and practicality and works well for those when an aptitude in mathematics, sciences, engineering, and technology.

What Does it Take to Become a CNC Machinist?

Does the world of CNC interest and excite you? Here’s how you can become one.

While each employer will have different requirements for hiring, there are many paths that you can take to pursue becoming a computer numerically controlled machinist.

Typically, some higher education is required to start working within CNC, specifically areas of math, engineering and computer sciences. Some degrees that may work well for following a CNC career path are machining and manufacturing, industrial engineering and industrial automation engineering technology.

Furthermore, an apprenticeship through a trade school or community college program will skyrocket your CNC career to success. These programs last for roughly four years and frequently are paying while you are taking classes and learning critical on-the-job skills.

An apprenticeship-style education environment is indispensable in careers like computer numerically controlled machining. They are so useful because it may provide you with a job opportunity with the company you apprenticed with, once your program and degree are complete.Â

Do you see how huge this is? With a paid apprenticeship to become a CNC machinist, you can focus on gaining experience and knowledge in your field without the additional burden of making an income. On top of that, it creates a higher education environment where you’’ start out making money, rather than in piles of student loan debt.   Â

Here are some colleges to look into to kickstart your CNC career:

- Universal Technical Institute

- Lincoln Tech

- Sullivan University

- HoHoKus School of Trade & Technical Sciences

Once you’ve landed your dream job as a machinist, you can expect a median salary of around $43,630. That CNC machinist salary will vary depending on your place of employment and cost of living.Â

Summarizing it All

This unique career path is ideal for those who love math, engineering, science technology, and hard work. With so many educational and career opportunities to capitalize on, this career is tailored for those who dream of being innovative.

CNC machining is the perfect combination for those who enjoy working closely with technology while still getting to be hands-on. If you are looking for a job with a new problem to solve every day, machining may be the career path for you.

For more information on CNC machining, manufacturing quotes, or employment opportunities contact United Scientific INC. in St. Paul Minnesota today by phone at 651-483-1500 or by email at [email protected].