CNC lathes and CNC mills are the mainstays of any machine shop. They both perform subtractive machining processes by starting with a block of material and removing material until the finished part emerges.

Although both started as manually controlled apparatus, they are now both capable of being operated by Computer Numerical Controlled programming.

At United Scientific, we have all the equipment and experienced personnel needed to assist our customers with any large or small scale projects. We have what you need from prototyping to producing parts with 99-plus percent accuracy to inventory solutions. Contact us today for more information.

Method of operation

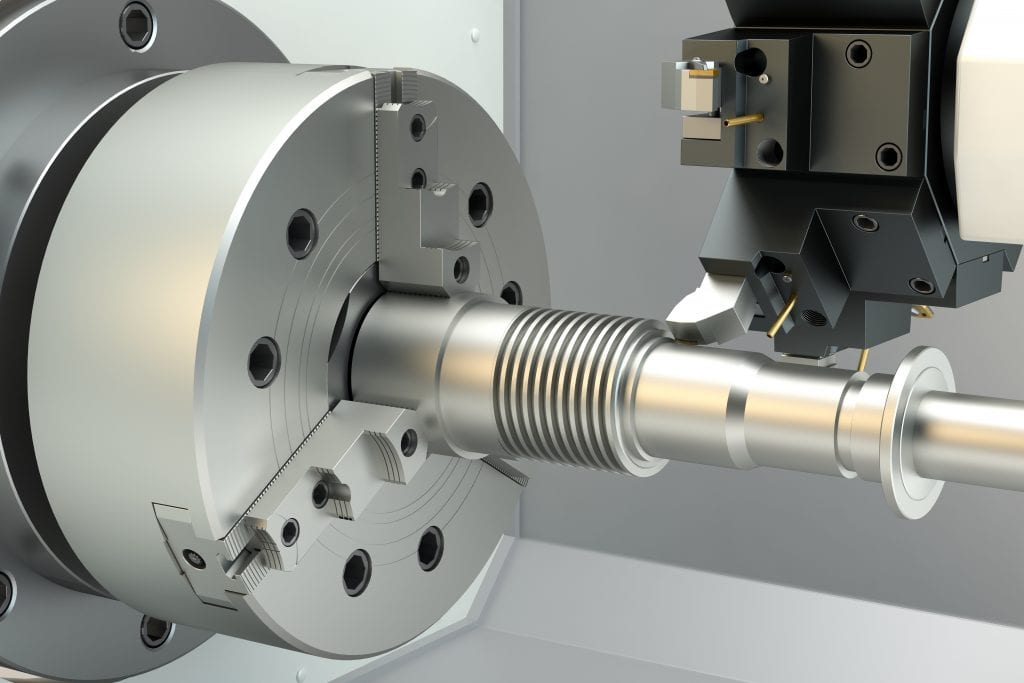

Both the CNC lathe and CNC mill produce precision components, but the process they use to get there sets them apart. The CNC lathe spins a block or cylinder of the workpiece in a chuck, and a static blade is applied to the surface of the spinning stock to remove excess material.

The lathe is considered to be a bit less precise than the CNC mill but is the go-to machine for quick, repeatable, symmetric components. The CNC lathe is best at forming cylindrical, conical, or flat surface shapes.

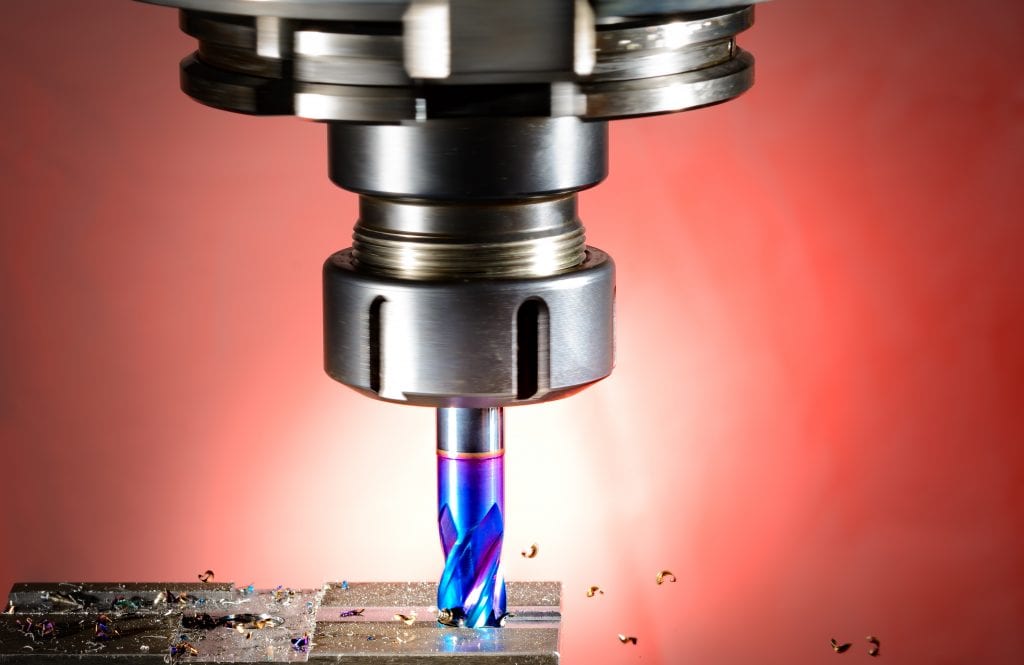

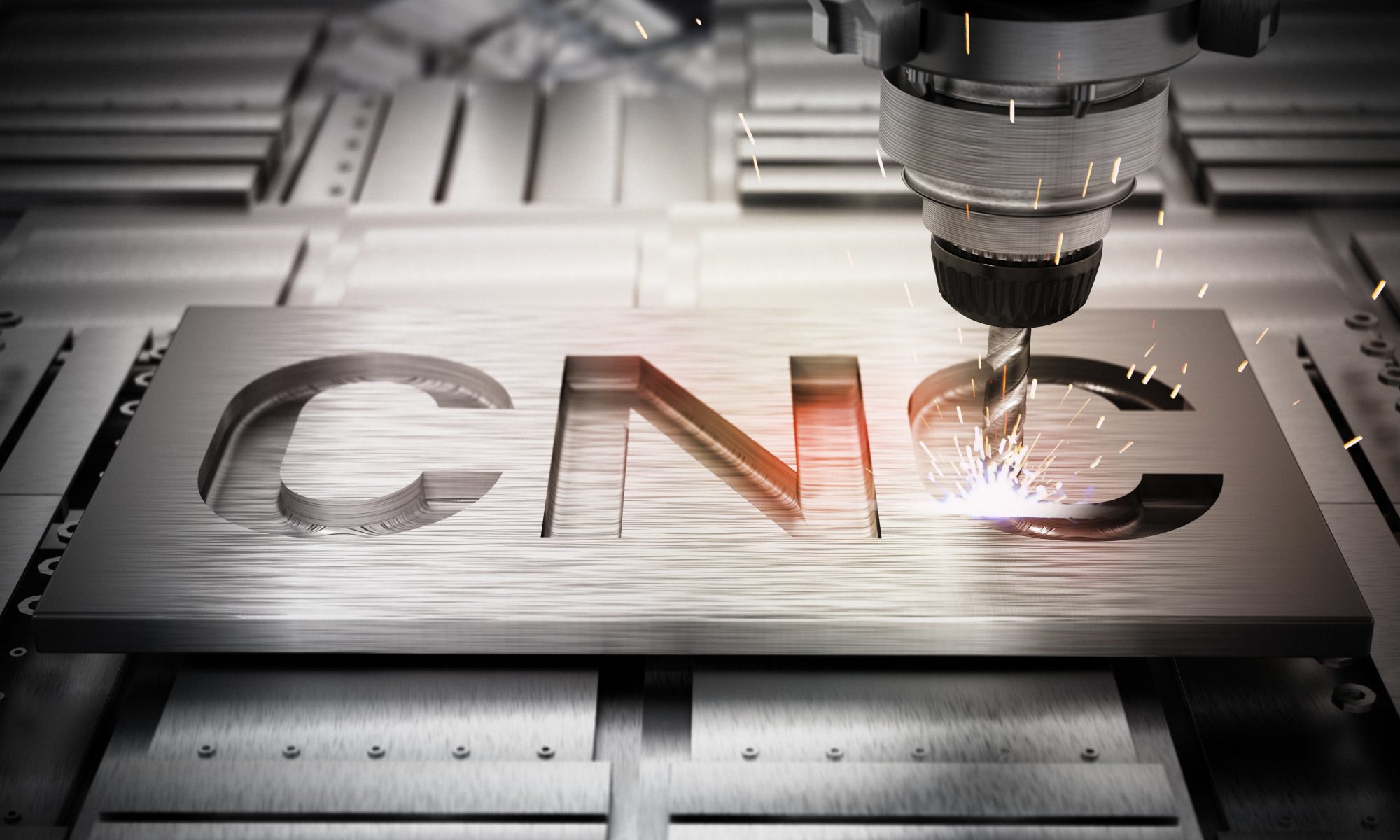

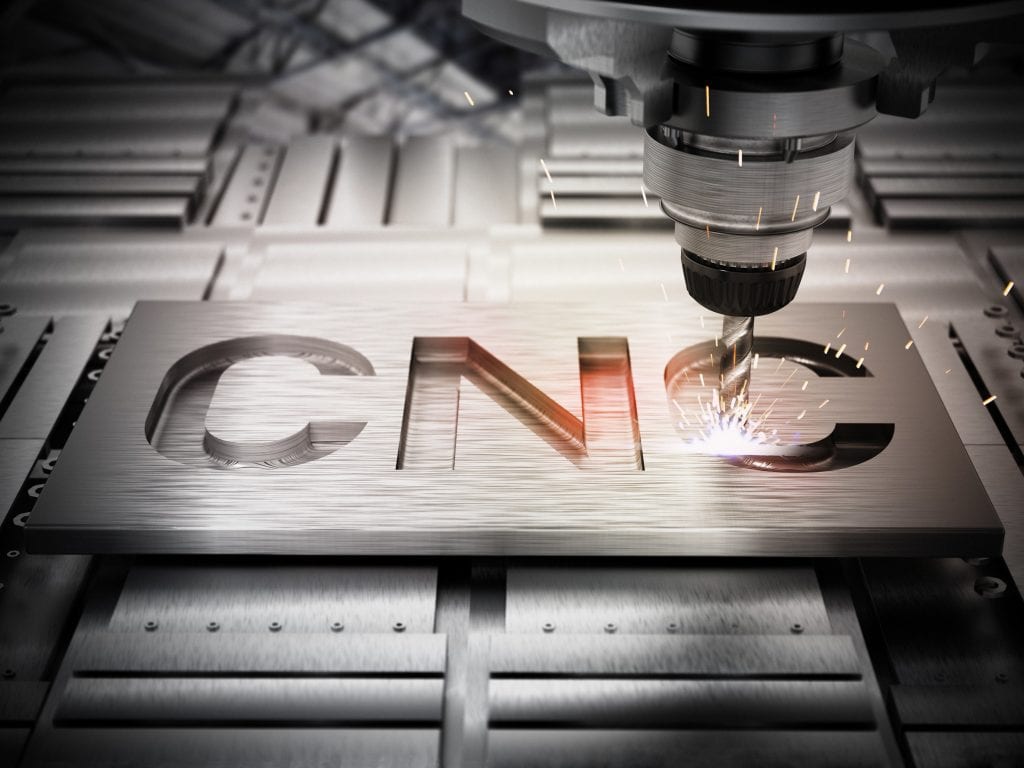

The CNC mill, on the other hand, holds the metal stock in a vice, and the cutting tools spin on their axis to create precise cuts in the material.

The mill is commonly thought of as more precise and versatile than the CNC lathe.

What does the CNC lathe do?

The CNC lathe, although limited mainly to cylindrical and conical shapes, does have several machining processes it can apply. This machine can still do some very customized types of machining:

Knurling is the procedure of imprinting a diamond shape or straight-line pattern into the surface of your metal component. This imprinting is accomplished by applying specially shaped and hardened metal wheels to the surface. The result is a better gripping surface on the final part.

Drilling creates holes in the workpiece. You can either use a CNC mill or CNC drill. However, if this is the only other operation needed to complete a part formed on a lathe, it is more cost-effective to drill in place and then use one of the following procedures; boring, reaming, or tapping, to complete the project.

Boring removes material from an inner surface with a single-point cutting tool, resulting in an enlarged and trued up a hole. Drilling is usually not an accurate method for hole placement, thus the need to drill an undersized hole and then enlarge and true-up, by the boring process.

Reaming is the operation used when you only need to finish up the surface of the already drilled area. If your hole is drilled to within 0.004 to 0.012 inches of its finished size, you may need to use a final reaming procedure to bring the part up to spec.

Tapping is the operation used to add screw threads to your pre-existing drilled hole. Like the initial drilling, you can accomplish this on a CNC mill machine as well, but it may be more cost-effective if this is the only additional physical feature to add.

Eccentric turning is when a component has multiple holes with offset axes. Crankshafts and camshafts are examples of where this technique is employed.

Facing creates a flat surface, perpendicular to the axis, at the end of the piece.

Chamfering creates beveled edges on the workpiece. A bevel can soften the side of the piece created by facing and may facilitate assembly with mating parts.

What does the CNC mill do?

The CNC mill is considered more precise and versatile than the lathe and can perform numerous different operations as well. A mill also has more cutting blades and is capable of cutting out more intricate designs.

Drilling can be done on a milling machine if the hole you are creating is greater than 1.5mm, and its depth is less than four times its diameter. It is best to complete anything smaller or with more depth on a drilling machine.

Slot cutting involves cutting grooves, usually using side and face cutters, to any length, width, and depth your material will allow, and can be open or closed. You can also create pockets, or non-circular cuts into a material surface, using slot cutting.

Planing is a process similar to using a woodworking planer but on metal. One use for this process is to reduce the thickness of a metal plate.

Rebating cuts grooves or slots into the edge of a piece for visual appeal.

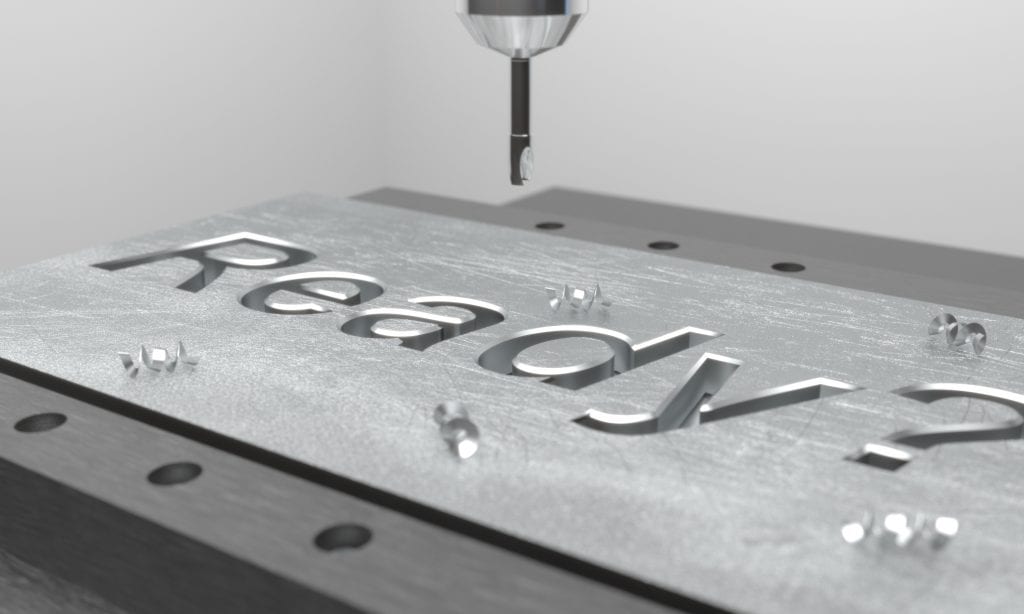

Engraving is the art of carving a design into a surface. A CNC milling machine is capable of engraving anything from a serial number to elaborate artistic embellishments.

Compare and contrast

Although initially intended to cut metal, current machines can cut foam, plastic, and fiber-reinforced plastics as well as a wide range of metal and metal alloys.

Both the CNC lathe and CNC mill are invaluable pieces of equipment. Each with its distinct uses.

The CNC lathe is simple to use and simple to program but is somewhat limited to cylindrical and conical turnings.

As described above, the CNC mill is the workhorse of the machine shop. The milling machine is versatile, consistent, and with a little maintenance can run continuously for long periods.

There is a difference in the installation process of each machine. The CNC lathe requires the chuck jaws installed at an equal distance from the center. Therefore, requiring many measurements. While setting up the CNC mill machine is less complicated.

The only drawback is that with more complex finished pieces comes more complex programming, exact tooling requirements, and the use of coolant and other process adaptations to keep machine and tooling maintenance to a minimum.

Whether you are looking for quick, repeatable pieces manufactured on a lathe, or complex shapes and surfaces requiring intricate CNC programming, United Scientific is ready to handle your request. Our machinists deliver on time and with 99% accuracy. We can even help you with everything from your upfront prototyping to innovative inventory solutions.

Contact our expert staff today to get started on your next project.