In the world of CNC (Computer Numerical Controlled) machining, precise cutting technique and certain finished products rely on so much more than computers alone.

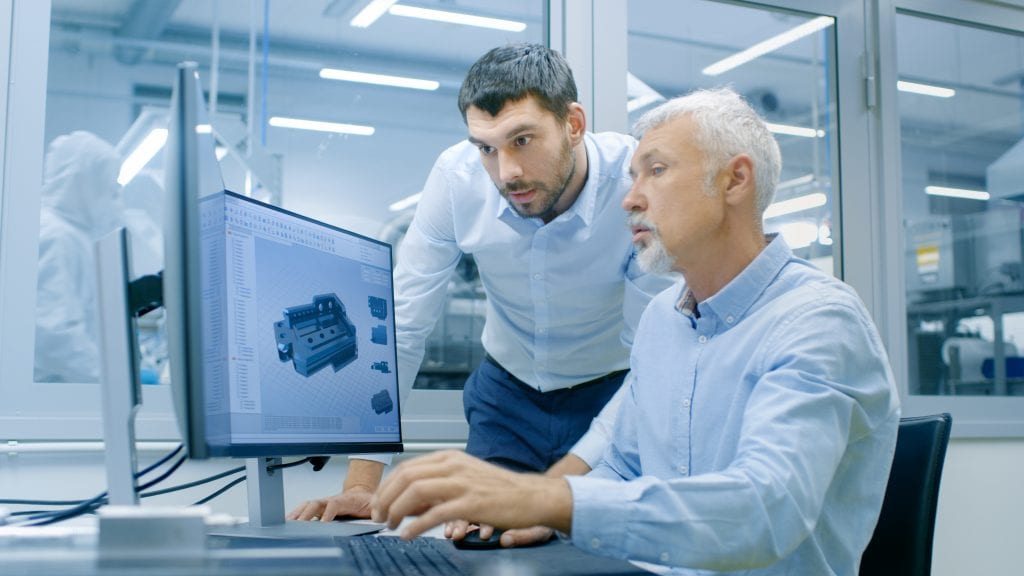

Though digital design and cutting instructions have improved part accuracy several-fold over the years, a significant amount of “art†and user experience accompanies the science of superior cutting for every CNC programmer.

Whether you’ve just graduated from a CNC program or have been turning parts for years, the following tips and tricks can help you refine your skills and improve your accuracy outcomes.

For a reliable partner in CNC machining across a wide range of projects and industries, contact United Scientific. Our accuracy is second-to-none at 99-plus percent, and we can handle any size job from small custom part orders to large-scale machining collaborations.

Call us today for the parts you require, the delivery you need, and the service you want.

Revisit the basics often

Though CNC programmers often get more skilled with time and practice, the best machinists rely on the consistent practice of CNC fundamentals. When’s the last time you:

-

- Checked your math: with each project you machine, it’s smart to “measure twice and cut once,†as the saying goes. In your design phase, be sure to measure the specs carefully you’ll need for the finished product or part and check your programming directions in your CAD software. Be mindful of software limitations like curved lines. Many programs plot out curves or circles as a series of chords rather than a true curved surface. Digital part precision is only as good as the math used to create it. Here’s a trusted resource for brushing up on your measuring and geometry skills, as they pertain to CNC.

- Honed your critical thinking skills: in the field of precision machining, it’s essential to make sound decisions on the fly, especially in large-scale projects that depend on accuracy as well as efficiency. Refining your measurements, tolerances, and finished surfaces is a continual process as the job rolls out. Staying vigilant with the quality of your output and diligence of your operator team is crucial to achieving the highest accuracy and functionality with each part or project you design. Good CNC cutting and turning are not about “setting it and forgetting it.â€

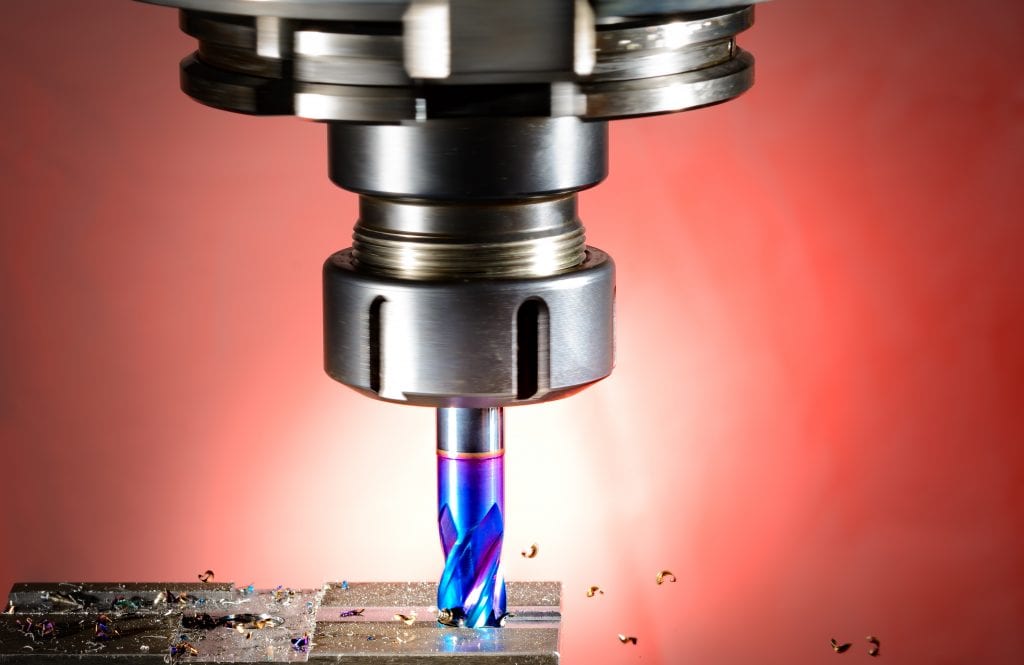

- Got to know your machine from a programming standpoint: CNC programming is all about a unique form of communication. CNC programmers must be skilled linguists and translators in both machine and programming languages. Knowing your machine’s axes (3 or 5?) components (spindles, blades, and stages), and programmable functions and visualizing how the machine will carry out your design are essential to programming a functional, precise part.

Now, refine your technique

Here are several ways to improve your programming, cutting, and finishing on your next projects.

- Perfect your 3D modeling. A perfected design results in a more precise product.

- Use a heavy sacrificial block to minimize vibration

- For example, if your part material is relatively lightweight, like with plastics, or metals like aluminum, a heavier sacrificial block placed beneath your machined block can reduce micro errors or rough finishes caused by excessive vibration. If your machined material is plastic, place two sacrificial blocks as a foundation, one matching the machined material, and one of a heavier weight for vibration reduction.

- Assume there will be errors, and design with them in mind. If you know your machine has limitations on things like precise edges, inside curves vs. outside curves, and more, allow for those errors and troubleshoot them in the design phase.

- Consider accuracy and machine wear-and-tear trade-offs. In other words, if you know your machine will deliver a laser-fine edge but will need to spend 3 hours doing it, decide how to prioritize the longevity of your machine over the precision of the edge in question.

- Place as many alignment features as possible on the same side of your piece. Having to drill or cut multiple alignment features like holes for screws or dowels on opposite sides of a plate increases the risk for errors. Address this issue in your design and programming phase for more finished pieces that work like they’re supposed to.

- Carefully prep your cutting surface. Make sure each block to be cut has an even surface for taping (to the sacrificial block).

- Tape your material liberally to the sacrificial block before cutting. And, to guarantee effective adhesion, be sure both taped surfaces are smooth, clean, and damage-free, or else you may get unwanted slippage during the machining process.

- Don’t overdo the cutting fluid. You’ll need the lubrication and cooling that cutting fluid can provide, but too much can seep down between the sacrificial block and the machined block, causing slippage.

-  You can also use “roughing†to outline the final cuts of your piece before making them. This is where your mill traces an outline of your programmed cuts into your block, or cuts away the basic shape of your product before finishing the piece.

- Use bigger mills first and do as much with them as you can. This step increases efficiency and reduces wear and tear on your smaller mills and blades for your true detail work.

- Manipulate your machines’ feed rates for the best results. You may be able to use the factory presets on your machine, but sometimes a customizable feed is your best bet. As your project rolls out, be ready to adjust your feed times for optimal efficiency and accuracy once you begin getting data on the finished product.

United Scientific: your partner in CNC best practices

For accuracy, precision, experience, and expertise in CNC manufacturing, partner with United Scientific. Our team can assist you with all phases of the machining process, from design to finishing. Our 99-plus percent accuracy rating means your parts achieve optimal function and tolerance every time.

We handle small and large projects, and everything in between, customized to your unique applications and specifications. We always measure (at least) twice.

Contact us today to get started producing the precise parts you need for any size project in nearly any industry.