The manufacturing world has transformed drastically over the decades as materials have become stronger, lighter, and more readily available. One of the most innovative changes has been the introduction of fiber-reinforced plastic. This incredible product helped revolutionize many industries.

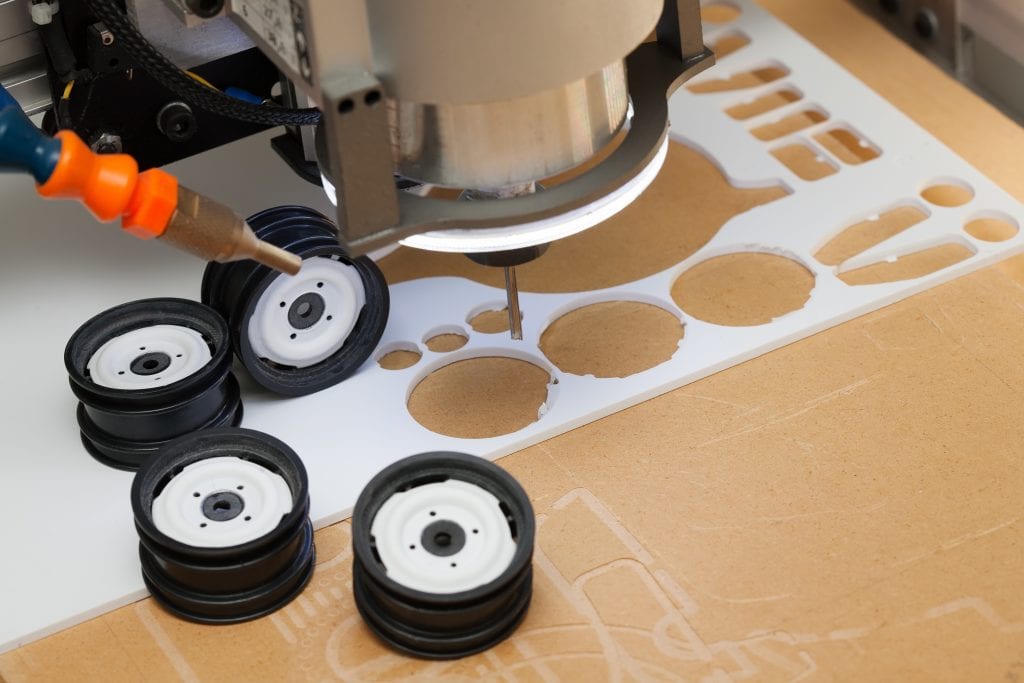

With the advent of CNC machining, fiber-reinforced plastic (FRP) now has many applications. The experts at United Scientific Inc. use computer numerical control processes to craft what you need from FRP for all your design and building needs. We work with expertise, accuracy, and precision on all of your projects.

If you’re ready to see what FRP can do for your business, take a look at all the possible applications.

What Is Fiber-Reinforced Plastic?

Also called fiber-reinforced polymer, FRP is a composite material. It consists of a plastic matrix that has fibers in it made of a different material. These fibers are usually glass or carbon, and they serve to reinforce the plastic to make it stronger without adding significant weight.

The plastic matrix, on its own, is prone to breakage under high heat or pressure. It is quite weak. But with the addition of the fibers, the product suddenly can handle more demanding tasks. This strength, without a lot of weight, makes FRP an ideal product for many industries.

Benefits of Fiber-Reinforced Plastic

This incredible material offers tremendous advantages over stand-alone plastics.

- Corrosion Resistance – Because of its ability to maintain integrity, even in water, FRP is excellent for maritime applications. The material remains intact, no matter the environment.

- Lightweight – FRP is exceptionally light for its strength and durability, making it perfect for civil engineering and aerospace projects.

- High Strength – The simple addition of fibers to the plastic matrix vastly increases the strength of the product. FRP is highly valued in civil engineering and seismic retrofitting projects for this reason.

- Impact Resistance – Panels made of FRP retain their shape and integrity even in collisions.

- Moisture Resistance – Fiber-reinforced plastic won’t warp, crack, or mold when exposed to water. This property makes FRP perfect for oceanic uses.

- Environmental Friendliness – Since FRP has excellent durability on its own, it does not require hazardous coatings to protect it from the elements. FRP’s long lifespan means it does not require frequent replacement, so there is less waste.

- Cost-Effectiveness – Compared to other high-end or unique building materials, fiber-reinforced plastic tends to be lower in cost and much more economical.

- Exceptional Thermal Properties – FRP products provide excellent insulation, making them the perfect choice for many uses.

Engineers, designers, and builders know that FRP is a game-changer for their businesses. With the availability of this incredibly durable, lightweight, and relatively inexpensive product, the sky’s the limit.

Who Uses Fiber-Reinforced Plastic?

FRP panels show up in all kinds of applications. No matter where you are in the supply chain, there is likely to be a use for fiber-reinforced plastic. The highly-prized benefits of this material make it ideal for parts manufacturers, designers, and builders. The top industry users of FRP are:

- Aerospace Industry – The high strength and low weight of FRP make it perfect for aeronautical applications. Aerospace engineers and design teams require materials that can withstand significant pressure and can handle vast changes in temperature. Fiber-reinforced plastic fits the bill.

- Maritime Industry – Because FRP is less likely to corrode than other materials, it is an ideal candidate for shipping and oceanic purposes. The strength and low weight are also necessary for this industry.

- Civil Engineering – Structural projects such as bridges, skyscrapers, and seismic updates benefit from the use of fiber-reinforced plastic. In particular, FRP is ideal for projects that involve retrofitting and upgrading existing structures.

- Automotive Industry – With an unmatched strength-to-weight ratio, FRP is perfectly-suited to car manufacturing. From gas pedals to intake manifolds, this miracle product provides just what the engineer and design crews need to make their ideas a reality.

- Construction Industry – Aluminum doors and windows often have FRP coatings for insulation.

- Sporting Goods – FRP no longer exists solely in big engineering industries. It is making its way into homes, gyms, and clubs as part of sports equipment. Hockey sticks, rackets, and bike frames can all make use of FRP products. Sporting items with fiber-reinforced plastic are very lightweight, improving the player’s performance.

- Other Consumer Goods – As FRP becomes more mainstream, it’s showing up in guitar picks, violin bows, instrument cases, and remote-controlled items. Drone manufacturers also rely on fiber-reinforced plastic.

Can CNC Machinists Work on Fiber-Reinforced Plastic?

Not all machinist shops can work on FRP. At United Scientific Inc., however, we are proud to provide excellent FRP work for our clients. From small and intricate parts to large panels, we can deliver what you need.

FRP is valuable to many industries and for a wide variety of uses. The CNC machinist works with precision and care to create what the customer requires. The USI team is proud to offer this service to our clients. Here is some of what our expert crew provides:

- Molding

- Extruding

- Laminating

- Drilling

- Forming

- Assembly

- Stamping

- Deburring

- Swiss Screw Machining

Whether you need a part that is big or small, our team can craft it for you with accuracy and skill. We create the quantity you need when you need it.

Fiber-reinforced plastics have changed the face of manufacturing across all industries. Designers, builders, and engineers have almost limitless choices now thanks to FRP products. And planes, trains, and automobiles are built stronger than ever.

United Scientific Provides Expert CNC Machining

No matter what parts your company needs, the USI machinists can deliver. Fiber-reinforced plastics offer almost unlimited options in size and configuration. And the United Scientific CNC machinists are up to the task.

Whether you need a single prototype or thousands of parts, our team can get the job done. We have the highest-quality technology and expert staff to create just what you need. Our machinists deliver on time and with 99% accuracy.

As leaders in the machining world, we serve a range of industries, including aerospace, defense, automotive, and agriculture. Reach out today to the most trusted name in machining to get your project underway.