Making the right manufacturing choices is crucial for quality products and a successful business.

If you’re involved in designing, building, sourcing, or purchasing metal components, you’ll want to understand the differences between subtractive and additive manufacturing.

You’ll also want to know when it’s better to choose one of these manufacturing methods over the other.

There are a few things you’ll want to know about your finished part when choosing between subtractive and additive manufacturing. For example, the size, the volume, the finish, and the materials used all affect the decision.

Here at United Scientific, we’ll help ensure your parts manufacturing choices meet all your needs. We’ll help you determine what is the best parts manufacture process for your project — subtractive or additive manufacturing.

What’s the difference between subtractive and additive manufacturing?

It’s easy to remember the most significant difference between additive manufacturing and subtractive manufacturing. Here’s why: the two terms mean just what they sound like they say.

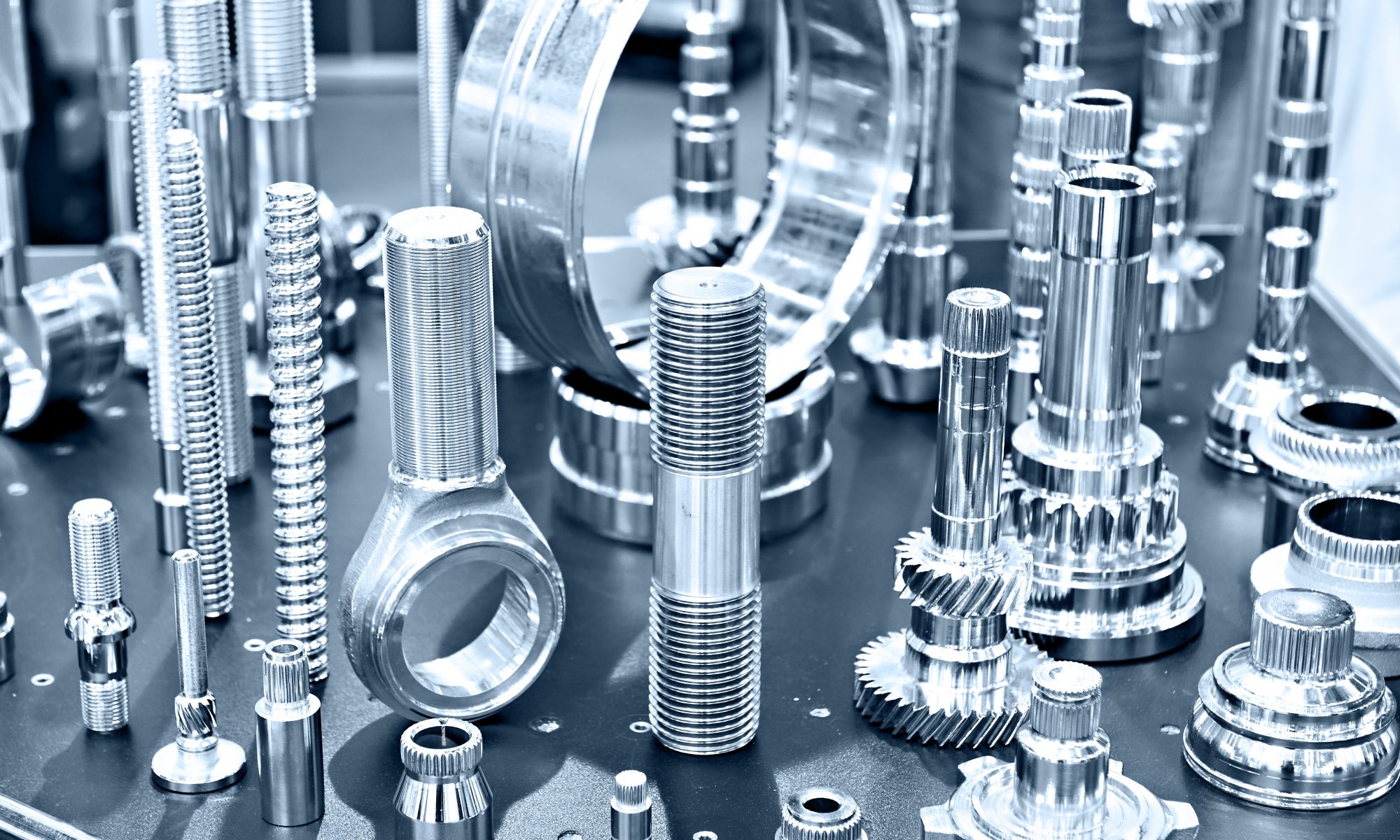

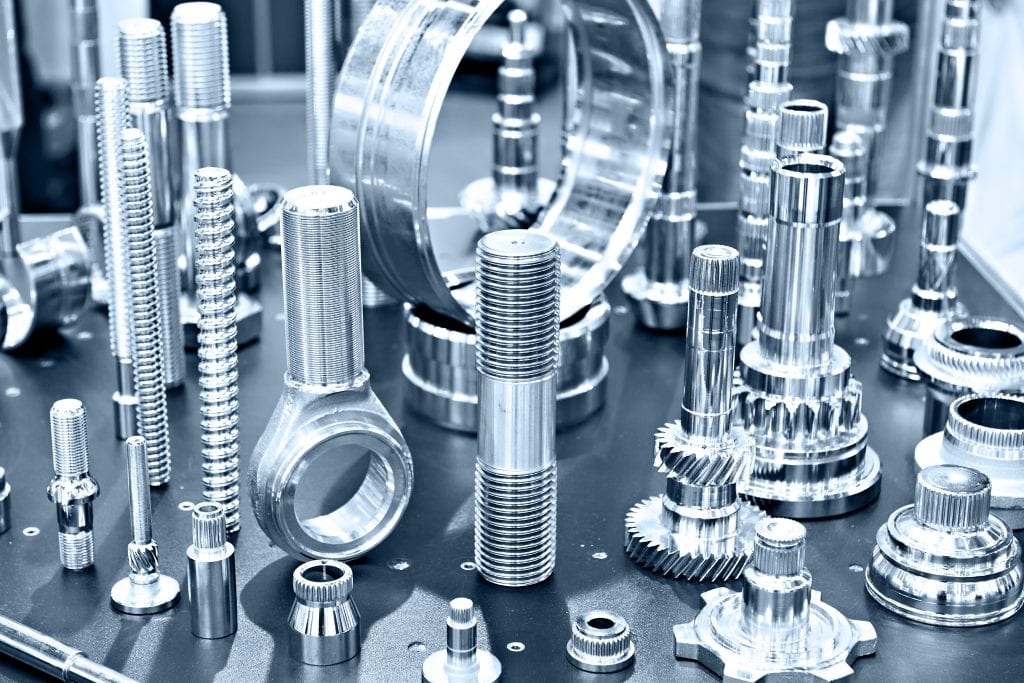

Subtractive manufacturing starts with a single piece of material, such as metal, glass, or plastic. There are also some composites and woods that can be used.

Then, the manufacturer removes any part of the material not needed until only the desired manufactured product remains.

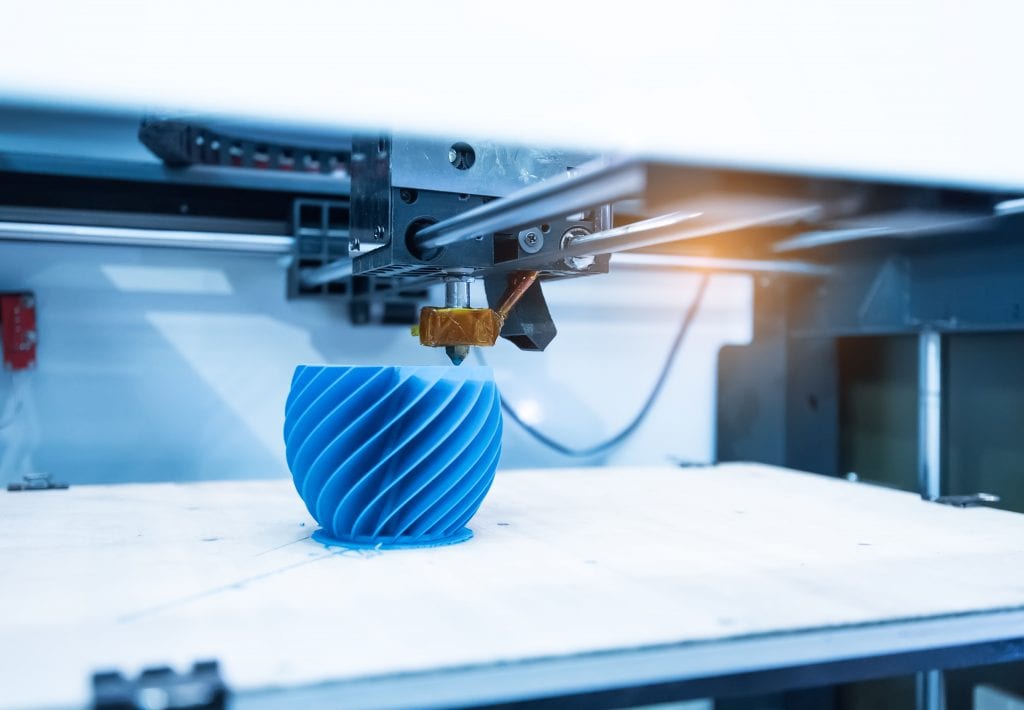

Additive manufacturing analyzes the finished product and then builds it “from the ground up,†layer by layer. Once all the layers are assembled, the product is complete. Materials are often plastic composites and may be more flexible.

More About Subtractive Manufacturing

Here’s an easy way to understand subtractive manufacturing: Visualize a sculptor chiseling away marble to leave behind a beautifully detailed statue made out of one piece of stone.

Subtractive manufacturing is a similar process. You start with one solid piece of material, and sections are removed until you’re left with the finished product you want.

The removal process can be done manually, but most often, it’s done with Computer Numerical Control (CNC) machining. CNC uses computer technology to ensure the removal process is precisely accurate and replicable on a large scale.

Now, you might be wondering: how is the material removed? Lasering, drilling, and boring are just a few of the ways unneeded sections can be removed.

Many different materials can be used with subtractive manufacturing, but aluminum and stainless steel are popular options. Glass, nylon, and composite materials can also be used.

More About Additive Manufacturing

Additive manufacturing builds a part layer by layer. Often, a computer program like CAD is used to create a 3D model that is then “sliced†into layers that the 3D printer (the most common additive manufacturing tool today) produces.

Parts made from additive manufacturing may need additional work after they are manufactured. For example, the finish may be wrong, or there may be support structures that need to be removed.

There are many different materials that can be used in additive manufacturing, such as nylon or resin. However, material selection is more limited in additive manufacturing than in subtractive manufacturing.

When Should You Choose Subtractive Manufacturing?

You might want to choose subtractive manufacturing if:

- The part is made of metal. While it is possible to use metal in additive manufacturing, it’s usually cost-prohibitive.

- Durability is important. Because the item is from one solid piece, there are no seams or weak spots. The durability of subtractive manufactured goods has made them a popular choice for aircraft manufacturing, for example.

- You want a smooth finish. The lack of lines might mean less work post-manufacturing, depending on your desired outcome.

- Stringent specifications or sharp angles are required. Using CNC machining results in more consistency and detailed precision.

- The part is needed in high volume. Subtractive manufacturing with CNC machining is fast and is an excellent choice if you need a large number of identical parts.

- Industry qualified materials are required. The automobile industry is one industry that relies heavily on subtractive CNC manufacturing.

- The part is large. Building a large part from “nothing,†as is done with additive manufacturing, can take a long time and diminish the stability and sturdiness of the piece. On the other hand, subtractive manufacturing is a quicker process.

- There is a near-net-shape part produced by additive manufacturing that needs to be finished. Hybrid manufacturing is an option, and subtractive manufacturing is usually the last step.

When Should You Choose Additive Manufacturing?

You might want to choose additive manufacturing if:

- The design is exceptionally complex geometrically. Intricate models and minor changes are more difficult and costly to make with subtractive manufacturing.

- Only a few copies of the part are required. Additive manufacturing can be an excellent choice for prototypes or samples.

- The turnaround time is incredibly short. It is quicker to program a 3D printer than a CNC subtractive machine, so if you need your part in a day, choose additive manufacturing.

- The material for the part is flexible. Subtractive manufacturing works better with more rigid materials.

- Limiting waste is crucial for your business. Since the part is built layer by layer, there’s less wasted material to discard when finished, and compostable plastics can even be used. (However, it’s not entirely waste-free and will still require waste-management efforts.)

- The part has a hollow center. Additive manufacturing is more efficient at creating pieces with hollow interior sections.

- The part is small. The layered construction method means the finished product isn’t as structurally solid as an item manufactured subtractively.

Can you use both additive and subtractive manufacturing together?

Some clients find that the best way to complete a project is to create a hybrid part, one made using both subtractive and additive manufacturing.

Typically, a hybrid manufacturing process means the geometrically complex pieces are completed using additive manufacturing. Then subtractive manufacturing is used for precision elements.

Need help getting started?

Starting your manufacturing process right is essential. Reach out to United Scientific today to discuss your manufacturing needs and how we can help you fulfill them.