Modern manufacturing companies across the globe continue to innovate their industries with its ability to morph from impossibilities into legitimate and precise, computer-controlled results. The introduction of the computer was the catalyst driving society to recognize our potential for incredible growth. United Scientific Inc. has been in business for over 70 years utilizing the very best for their customers, call today to get started!

There are computer-controlled manufacturing methods today, known as computer numerical control or CNC as opposed to the labor-intensive and incredibly unsafe practices of the industry’s first revolution. We are now in the fourth, known as industry 4.0 referenced on-the-dot for the integration of computers into manufacturing.

Subtractive, additive and formative are methods of manufacturing used in the 21st century by businesses depending on their field. United Scientific Inc in St. Paul, MN uses top-of-the-line equipment, including the highly trained quality control department. The quality control department ensures every order is filled and delivered on time, as it should be.

Types of manufacturing

Additive, subtractive, and formative methods are the three categories of manufacturing.

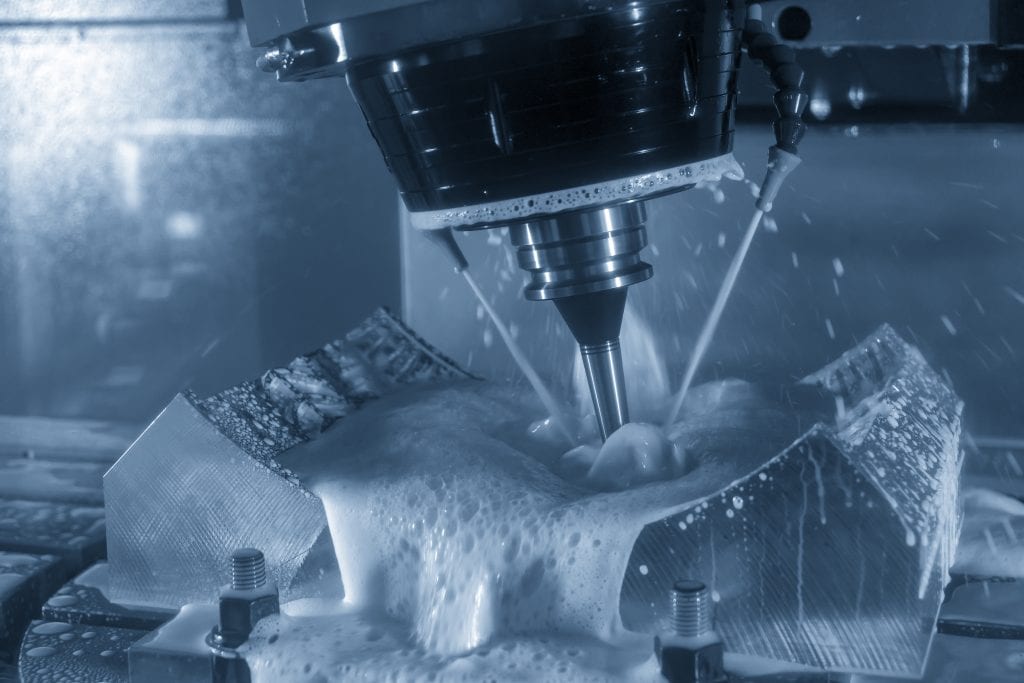

Subtractive manufacturing is the most utilized type of production today. Although 3-D printing has had many strides in the last decade, the cost and manufacturing time have held 3-D printing back from entering the mainstream on a full scale.

3-D printing is a type of additive manufacturing – adding material layer by layer to eventually build a product. Powder metal is one substance used in additive manufacturing or 3-D printing, layering the material layer by layer until the design is complete. This method is captivating, although too slow to compete with the widely used subtractive process combined with the CNC machine.

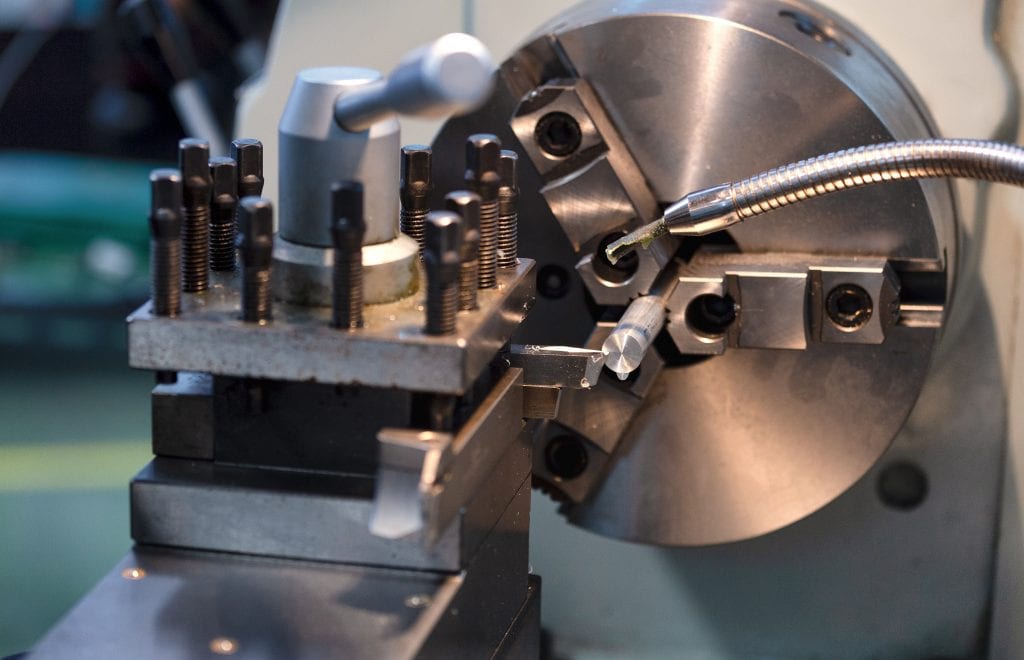

The opposite is Subtractive method – removing material from the object the machine is shaping. Removing the subject medium being the most efficient type is utilized by several means, including laser and router. Computerized Numerical Control devices are often used in modern manufacturing for items such as gears, proprietary designs, everyday bolts, and collaborate designs.

Third, Formulative manufacturing – this is molding or casting material to solidify into negative space, forming a positive result. Resin molds are popular these days, as well as an example of a formative method of production. The resin is poured into a mold and left to solidify, leaving the positive image.

Products you would see created with these methods commercially use a CNC machine, machinist, and programmer for quality and quantity efficiency. Machinist learns the individual devices they use in conjunction with the CNC component. United Scientific Inc., for example, makes sure their employees are well informed, trained, and certified for their state-of-the-art equipment.

What is Relatable to Me?

CNC projects or products are most commonly internal parts of a whole, also known as subtractive manufacturing. The general public would see a CNC router, producing engraved wooden signs in contrast to hand-carved signs seldom produced. Routers can create some artistic pieces using a variety of materials. Everyday modern items you need a CNC device to produce:

- Your smartphone

- Aeronautics

- Military equipment

- Weaponry

- Production line machines

- Vehicles

- Medical equipment

- Some styles of artwork

The items listed above are the completed product in which computer-controlled machines cut, lathe, mill, and drill on several axes’ for the unbelievably fast result in modern manufacturing today. Given this technology and the introduction of the additive method 3-D printing, we are to expect surprising things in the future. We may even see flying cars from The Jetsons finally.

CNC machines in modern manufacturing are rapidly filling the demand of other manufacturers and advancing their output. Integral components created using computer-assisted technology has grown the industry, making parts efficiently, giving the end-user access to products once unavailable. The ability to mass-produce a mechanism is a great leap forward for humankind.

On a Serious Note

Modern manufacturing is at the beginning of a historical jump into the future. Science is at the forefront of this innovation craze, tech science to be precise. Artificial intelligence has been introduced on a publically usable scale, something we could not fathom without the technology innovations of the last few decades. A computer and printer can be the future of manufacturing, sending objects through a data stream printing on the other side.

We are witnessing the first-ever devices, such as Google Assistant and Siri, the general public can experience in their own homes. These machines continue to learn the habits of its user, sometimes knowing what you need before you do. Environment concerns will propel the modern manufacturer to upgrade and innovate, thus a need for additional development, safer equipment, and quicker turn-around times.

To Sum it Up

In terms of technology advances for manufacturers and the public alike, there are no limitations. Scientists, innovators, manufacturers, and programmers have created a new world to understand. Our goal as humans is to advance our knowledge, expand the possibilities in our minds, and explore the depth of so-called limitations we used to believe wholeheartedly.

Artsy CNC projects are fun and exciting at home with the right tools, equipment, and flare for computer design programs. The non-artsy person can dive into the world of creating by learning the software and applying it to their potential art! If you require large amounts of product, product storage, or design expertise, call United Scientific Inc. for your manufacturing requirements. Their results speak volumes.

Continuing population growth will ensure the need for manufacturing far into the future. Clearly stated there is no stopping point for our imaginations. The world of modern manufacturing will only grow – growing into a future we may not be able to imagine just yet. With 3-D printing well on its way to becoming a resource for building, we may see the far future sooner than we could have dreamed.